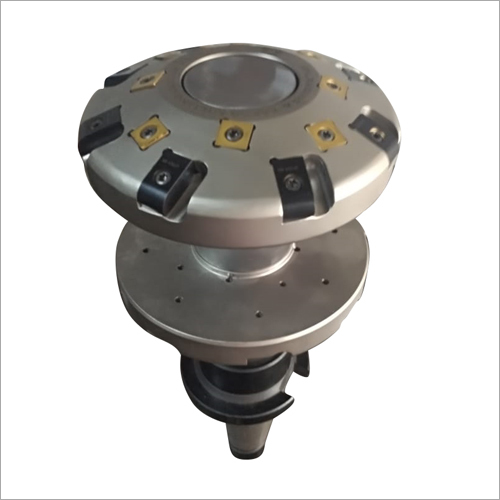

Side and Face Milling Cutter

Price 10000 INR/ Piece

Side and Face Milling Cutter Specification

- Product Type

- Side and Face Milling Cutter

- General Use

- Industrial milling operations

- Material

- High Speed Steel (HSS)

- Type

- Cutting Tool

- Capacity

- High precision cutting

- Weight (kg)

- Varies as per size (typically 0.5 3 kg)

- Cutting Speed

- Appropriate for HSS cutters, up to 150 m/min depending on material

- Cutter Type

- Side and Face Cutter

- Cutting Thickness

- Typically 3 mm to 20 mm

- Segment No.

- Multiple

- Size

- Standard sizes: 50 mm to 200 mm diameter

- Segment Type

- Teeth Segments

- Slot

- Keyed/Compatible

- Teeth Type

- Straight or Helical Teeth

- Drive Type

- Machine-driven (arbor or spindle)

- Voltage

- Not applicable (manual/mechanical tool)

- Feature

- Durable, precision engineered, corrosion resistance

- Color

- Metallic

- Heat Treatment

- Tempered for maximum strength

- Bore Size

- 16 mm to 32 mm standard

- Tolerance

- High (±0.02 mm typically)

- Surface Finish

- Precision ground

- Application Area

- Slotting, cutting, and parting in metalworking

- Packaging Type

- Box/Carton packaging

- Outer Diameter

- 50 mm to 200 mm

- Customization

- Available as per customer specification

- Number of Teeth

- 12 to 40 (varies by size)

Side and Face Milling Cutter Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 7-15 Days

About Side and Face Milling Cutter

Versatile Application and Advanced Features

Our Side and Face Milling Cutter is engineered for diverse industrial milling operations. Suitable for slotting, cutting, and parting, this cutter boasts straight or helical teeth, precision-ground surfaces, and high-tolerance capacities. Its application areas include heavy-duty metalworking and general machining. Noteworthy features such as corrosion resistance, high-speed cutting capability (up to 150 m/min), and durable HSS material make it ideal for demanding environments, providing efficient, reliable results across a wide range of machining media.

Sample Availability, Secure Packaging & Competitive Outlay

Samples of our Side and Face Milling Cutter are readily available for evaluation. Each cutter is packed with care in sturdy boxes or cartons, ensuring secure shipping and delivery. With FOB ports located in India, we guarantee safe and efficient order fulfillment. Take advantage of our lowest price promisethe outlay for these premium tools is highly competitive. Order now to experience superior quality at reduced risk and optimized cost, making your procurement process straightforward and rewarding.

FAQs of Side and Face Milling Cutter:

Q: How do I select the appropriate size and type of Side and Face Milling Cutter for my operation?

A: Choose the outer diameter, bore size, and number of teeth based on your machine specifications and the type of metalworking operation involved. We offer standard sizes from 50 mm to 200 mm in diameter and customizations to fit unique requirements.Q: What materials can be machined using this cutter?

A: Our HSS Side and Face Milling Cutter is suited for working with various metals, including steel, stainless steel, and cast iron, making it ideal for industrial machining, slotting, and parting tasks.Q: Where is the product manufactured and can it be exported internationally?

A: The milling cutters are manufactured in India by a reputed exporter, manufacturer, and supplier. We supply globally, ensuring compliance with international quality standards.Q: What is the process for ordering customized cutters?

A: You can request customizations as per your specific application needs by contacting our sales team. We offer modifications in size, number of teeth, and other parameters to match your exact requirements.Q: What benefits does the precision ground surface provide?

A: A precision ground surface ensures high cutting accuracy, smoother operations, reduced tool wear, and an enviable finish on workpieces, optimizing productivity and quality in your milling processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Tools Category

Railway Track Machining Special Milling Cutter

Price 10000 INR / Piece

Minimum Order Quantity : 2 Pieces

Cutter Type : Other, Disc/Segmented Milling Cutter

Teeth Type : Other, Special Profile Teeth for tough railway steel

Product Type : Railway Track Machining Special Milling Cutter

Drive Type : Other, Automatic/Electric/Hydraulic Driven

Long Edge Cutter

Price 10000 INR / Piece

Minimum Order Quantity : 2 Pieces

Cutter Type : Other, Segmented Blade

Teeth Type : Other, Sharp Teeth

Product Type : Long Edge Cutter

Drive Type : Electric

Face Mill Cutter

Price 10000 INR / Piece

Minimum Order Quantity : 2 Pieces

Cutter Type : Other, Face Milling Cutter

Teeth Type : Other, Helical and Straight available

Product Type : Face Mill Cutter

Drive Type : Other, Arbor Mount

Spot Face Tools

Price 10000 INR / Piece

Minimum Order Quantity : 2 Pieces

Cutter Type : Other, Replaceable insert or solid

Teeth Type : Other, Straight teeth

Product Type : Spot Face Tool

Drive Type : Other, Shank (round or straight)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry