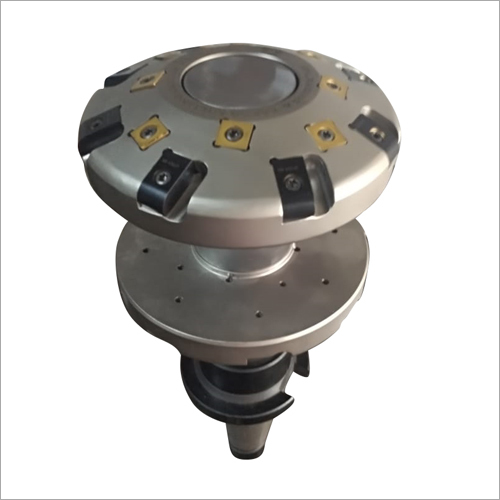

Face Mill Cutter

Price 10000 INR/ Piece

Face Mill Cutter Specification

- Product Type

- Face Mill Cutter

- General Use

- Industrial machining, metal cutting

- Material

- High Speed Steel (HSS), Carbide

- Type

- Insert Type

- Capacity

- Multiple cutting diameters (customized as per requirement)

- Weight (kg)

- 1.2 2.5 kg (approximate depending on size)

- Cutting Speed

- Up to 400 m/min (dependent on machine and material)

- Cutter Type

- Face Milling Cutter

- Cutting Thickness

- 2 10 mm (as per variant)

- Segment No.

- 4 8

- Size

- 50 mm 160 mm (diameter range)

- Segment Type

- Indexable Inserts

- Slot

- Open Slotting

- Teeth Type

- Helical and Straight available

- Drive Type

- Arbor Mount

- Voltage

- N/A (manual/mechanical operation)

- Feature

- Replaceable inserts, high precision, durable, anti-corrosive

- Color

- Silver, Black (coating dependent)

- Max RPM

- 6000 12000 rpm (depending on diameter)

- Shank Type

- Straight/Cylindrical

- Accuracy

- High concentricity and parallelism

- Application

- Face milling on mild steel, cast iron, aluminum, alloy steel etc.

- Surface Finish

- Polished/Coated

- Service Life

- Long (subject to operating conditions)

- Coating

- TiN/TiAlN (as per order)

- Insert Compatibility

- ISO Standard Inserts

- Corrosion Resistance

- Yes

- Pack Type

- Hard Plastic Case

Face Mill Cutter Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 7-15 Days

About Face Mill Cutter

Versatile Milling for Diverse Applications

Ideal for industrial machining, our Face Mill Cutter offers superior capability for face milling on mild steel, cast iron, alloy steel, and aluminum. Its use type supports both helical and straight teeth options, with segment numbers ranging from 4 to 8. The insert-type design, coupled with high concentricity and parallelism, ensures a smooth surface finish. Perfect for applications where precision and finish quality matter, this cutter adapts to varied job requirements across multiple surfaces.

Swift Supply and Global Delivery Promise

With a steady supply ability and robust manufacturing base, our Face Mill Cutter is consistently available at the lowest price. Quick dispatch is guaranteed, with average delivery times tailored to your order size and location. As a top exporter and supplier in India, we ensure your order is efficiently packed and delivered worldwide, serving main export markets in Asia, Europe, and beyond. Experience timely, reliable service that meets global standards for on-time delivery.

FAQs of Face Mill Cutter:

Q: How do I select the correct face mill cutter size for my application?

A: Choose your cutter size based on workpiece dimensions, required cutting thickness, and the machines spindle specifications. The available diameter range is 50 mm to 160 mm, with cutting thickness options from 2 to 10 mm.Q: What materials can this face mill cutter effectively machine?

A: This face mill cutter is suitable for machining mild steel, cast iron, aluminum, alloy steels, and various non-ferrous materials, making it a highly versatile tool for industrial environments.Q: When is the best time to replace the indexable inserts?

A: Replace the inserts when you notice increased cutting resistance, diminished finish quality, or inserts becoming dull or chipped. Regular inspection ensures optimal performance and extended cutter life.Q: Where is this face mill cutter manufactured and supplied from?

A: These face mill cutters are manufactured and supplied from India, exported to key markets including Asia, Europe, and other international destinations.Q: What is the process for replacing inserts on this cutter?

A: Simply unfasten the existing inserts and secure new ISO standard indexable inserts. Always ensure proper seating and tightening to prevent insert movement during operation.Q: What benefits does the coating (TiN/TiAlN) offer?

A: The TiN/TiAlN coatings provide enhanced wear resistance, lowered friction, improved corrosion resistance, and an extended service life, resulting in consistently high-quality machining outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Tools Category

Long Edge Cutter

Price 10000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, High Carbon Steel

Cutting Thickness : Up to 20 mm

Size : 14 Inch

Capacity : Heavy Duty

Side and Face Milling Cutter

Price 10000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, High Speed Steel (HSS)

Cutting Thickness : Typically 3 mm to 20 mm

Size : Standard sizes: 50 mm to 200 mm diameter

Capacity : High precision cutting

Railway Track Machining Special Milling Cutter

Price 10000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, High Speed Steel (HSS) / Tungsten Carbide

Cutting Thickness : 1025 mm

Size : Diameter 150 mm 300 mm

Capacity : Suitable for heavyduty railway track machining

End Mill Cutter

Price 10000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, High Speed Steel (HSS)

Cutting Thickness : 1 mm to 20 mm (varies per size)

Size : Diameter: 12 mm; Length: 100 mm (example size)

Capacity : Suitable for Cutting Mild Steel, Alloy Steel, and Cast Iron

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry